SV50 High Flow BOV

$367.00

T9050

The only BOV rated at over 300psi

(That’s more boost than 13 stock Mitsubishi Evo Xs combined!)

GFB’s New SV50; the highest flowing blow-off valve in the GFB range, capable of supporting IMMENSE horsepower!

What makes the SV50 stand out from the crowd?

Take note, diesel guys – the SV50 has the strength to withstand over 300psi without breaking a sweat! Try doing this with a diaphragm-type BOV!

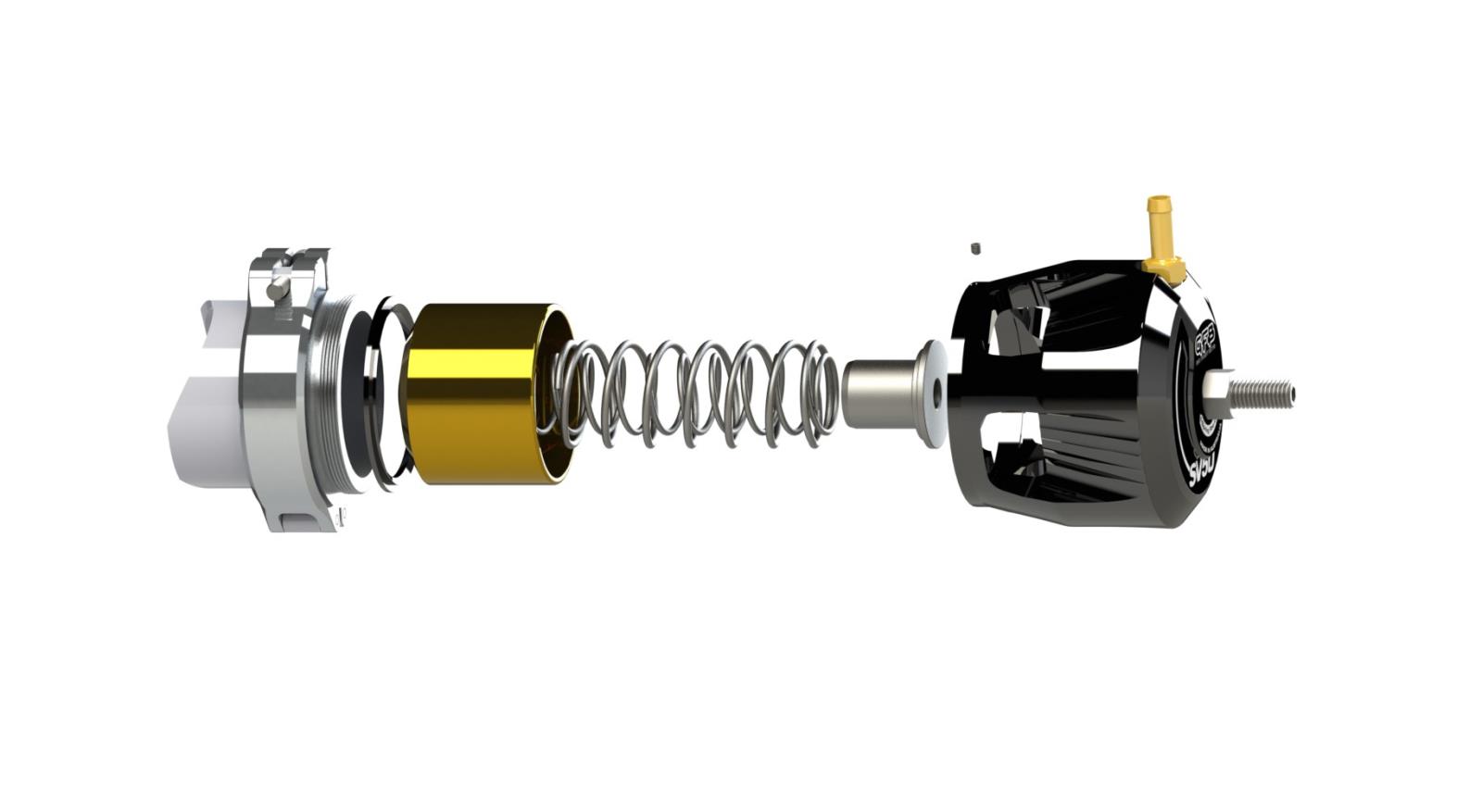

The SV50’s single-piece billet monoblock body design eliminates the need for fasteners and a separate cap, making it stronger and more compact.

The one-piece brass piston does not use a diaphragm. This ensures strength and reliability for the life of the valve.

Adjustability – other brands require you to pay extra for different springs to set the valve up to the engine’s idle vacuum. The SV50 can be used on applications with manifold vacuum ranging from 5-22”Hg (2.5-11psi vacuum).

New High flowing valve able to withstand immense pressures

Suits all High Powered Turbo or Supercharged Engines

The SV50 uses a v-band mounting system that is compatible with existing common v-band flanges. The billet hinged clamp design is both easier to use and stronger than other flexible band-clamp designs on the market.

Description

The SV50 is designed for one purpose only – to dump massive amounts of turbo pressure very rapidly, and

is intended for turbo or supercharger applications of 400hp or more. Whilst it can be used on

applications with less than 400hp, it would be considerable overkill, and other valves in the GFB range

will give better throttle response in such circumstances.

Why do we use a one-piece brass piston instead of a diaphragm like other brands?

For good reason – good quality diaphragms are typically constructed from silicone and reinforced with a nomex cloth, and are usually a“rolling” design that allows relatively long piston strokes.

However, this design has its limitations. The most significant being they are only designed to have pressure applied to one side, which is the underside. The nomex reinforcing is on the top of the diaphragm, so that the silicone is blown INTO the cloth. Applying pressure to the cloth side can result in the silicone material de-laminating from the cloth. Secondly, applying pressure to the wrong side of a rolling diaphragm causes the bellow section to collapse on itself. This creases the nomex reinforcing, and also causes friction and wear as the piston starts to move when the pressure changes to vacuum.

BOVs must deal with both pressure and vacuum, combined with the fact that competitors’ products use wastegate diaphragms constructed the wrong way around for use in a BOV, meaning a diaphragm is not the ideal solution.

By using a robust and proven piston design, and carefully machined to close tolerances, the SV50 eliminates the diaphragm and the problems associated with them when used in a BOV. This is how the SV50 can be made to withstand such high boost pressures.

image-3The SV50 comes with two springs and an adjustment screw, with which you can set the SV50 up for idle vacuum ranges from 5-22”Hg (2.5-11psi vacuum). This range covers anything from superchargers or all-out race cars, all the way to street driven cars with stock cams and high idle vacuum.

Other brands rely on swapping springs to set the valve up to the engine’s idle vacuum. Springs that you have to pay extra for.

The SV50’s v-band clamp is machined from billet, but that’s not the unique feature. Competitors’ one-piece designs rely on bending the clamp material to open up the clamp, with difficulty. Repeated bending will also cause the material to fracture. GFB’s 2-piece hinged design solves this problem by opening wide for easy installation and lasting longer than other designs.